1958 Ford Thunderbird Convertible Monogram Kit #96-4280 Review

RoR Step-by-Step Review 20111127* – 1958 Ford Thunderbird Convertible Revell Kit # 96-4280 Review Click Here to Buy This Kit

Â

Review and Photos by Stephanie and Marty Oberman

Â

The Revell ’58 Thunderbird 2n1 kit is actually a re-issue of the original Monogram kit in 1/24th scale introduced in 1987, although the copyright info inscribed on the latest re-issue dates it to 1964. I think ’87 is more accurate. An “Elvira” ‘Bird was also included in this series.

Â

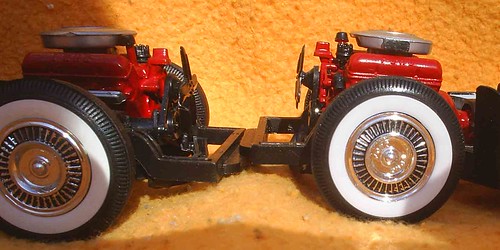

Fig 000a-b ) – I was issued a challenge to build not only this latest issue (left above), but the ’87 issue (right above) as well…kind of like a “comparo review”. I eagerly accepted the challenge. I could build the new issue as a custom and the older one as a stock vehicle, or, as I soon decided, build them together stock as a “His-n-Hers” duo. Since I’m not a big fan of customs, I chose the latter of the two options.

I started with the engines. There are no differences between the two issues’ engines; the tooling is the same. The two-piece blocks contain the tranny, heads, starter, and oil pan molded in. The carburetor is molded onto the intake manifold. There are separate valve covers, oil filler tube, distributor, coil, water pump, fuel pump, oil filter, fan belt assembly, fan, and exhaust manifolds.

Fig 001) – I began by assembling the block halves, valve covers, oil filler tube, water pump, fuel pump, and oil filter and painting them Ford Engine Red as a unit. I detail-painted the oil filler tube cap gloss black, the fuel pump bowl silver, and the oil filter itself my usual signature silver-base with Tamiya clear orange finish. The carb was detail-painted gold, the air cleaner aluminum, fan and pulleys black, and exhaust manifolds steel. The starter, distributor, and coil were painted black. Assembly of the engines on both issues was flawless, and as “crude” as the tooling may seem to be, they both build up to decently represent the venerable Ford Y-block V-8 .

I turned my attention to the chassis next. The chassis pan itself also contains the interior floor pan with molded-in console. The front suspension assembly is a 5-piece affair consisting of a lower suspension piece, two coil springs, and two upper A-arms. There is also an engine support brace which glues onto the chassis pan. As usual, I detailed the coil springs for realism, but when installed them into the chassis, they all but disappear. I decided not to do so on the other Bird. The front suspension assembled without issues, and looks rather nice for its simplicity. The newer issue contains a lowered suspension assembly for the custom version. The modeler should be aware that the stock suspension is part #2, and the custom unit is part #6. Not only are the part numbers listed on the trees, but the parts as well. Nice touch, Revell!

Fig 002) – The rear suspension assembly is where I ran into problems…at first. Upper arms and rear coil springs join together and mount into the chassis pan, followed by the rear axle/driveshaft mounting up underneath this assembly. I attempted to install all these items at once on the older issue, which proved to be a disaster. Thank goodness I’m building two of the same kit at the same time…I quickly learned my lesson. On the newer issue I glued the arms and springs to each other, mounted them to the chassis, then after the glue dried, mounted the axle to them. The rear shocks and sway bar then were installed with no issues.

The gas tank, mufflers, and rear exhaust pipes are molded into the chassis pan. I detail-painted these parts stainless steel before installing the rear suspension assembly. The front exhaust pipes are a separate piece which join to the ends of the rear pipes and exhaust manifolds. Although the front pipes do not join up well to the exhaust manifolds on the engine, they mate well with the rear pipes.

Fig 003) – The tires in both issues include separate whitewall plastic inserts, which I really like. In fact, the modeler needs to stretch the rubber tire around the whitewall piece to allow it to insert properly. This process ensures a nice, snug fit. I was very impressed with this aspect. The newer issue not only has stock Thunderbird rims, but also 3-bar custom rims for that particular version. Assembling the tires/rims/wheelbacks was a breeze…retainers are included in case the modeler wishes to have free-wheeling wheels. I left these out and glued the wheels straight to the axles. Fit was excellent. I detail painted the ribs on the outer parts of both cars’ wheels. I then installed the engine into the chassis, and mated it with the driveshaft with no problems. Two pins seat the engine into place and both engines were level when installed.

Fig 004) – I then turned my attention to the interior. This particular kit is quite unique in that the interior seems to be spread out all over the place, as it were. The interior door panels mount to the opening doors; the center console is molded onto the chassis pan, and the dashboard/steering wheel/steering column mount to the body. What’s left is a cut-up looking separate interior tub-style floor pan with rear seat molded in, and two-piece front seats that mount to the floor pan. The newer issue contains white decals for the seat inserts and side panels. The rear seat’s one-piece decals did not want to conform to the seat bench and back, no matter how I attempted to coax them into place. Even with setting solution they left a wrinkled look. My advice to the modeler who wishes to utilize them is to slice the decal in half where the seat back meets the bench once the decal is placed and begins to dry. Then he or she can better maneuver the decals separately to ensure a proper fit. If a gap remains between the bench and seat back after doing so, white paint may be added to touch up and hide the seam.

Fig 5) – The dashboard contains two chrome inserts: one for the instrument cluster and the other for the glove box. I detail-painted the inside of the three gauge housings flat black, then when dry, gently scraped a toothpick across them to bring out the raised numbers. I used a silver Sharpie to outline the radio housing, then detailed the radio face and buttons with flat black paint, using a toothpick.

The older issue’s steering wheel is molded in the same Seafoam Green color as the body. I left that as is and detail-painted the horn ring and rim silver. The newer issue’s body will be painted white, so I will leave the steering wheel on that car white as well. The remainder of the interior on the newer issue was painted satin black, which really accents the seat/side panel decals nicely. The center console was detail-painted silver on both cars.

Fig 006) – Moving on to the bodies I installed the interior door panels and side vent window frames and glass onto the exterior doors. Since both issues offer opening doors, I decided to maintain that feature. There are separate hinge plates for the doors which must be carefully glued into the interior body shell . Care must be taken not to get glue on the rounded parts of the plates, which would prevent the doors from opening properly. The instruction sheet wisely recommends that the modeler apply a piece of tape to the door to keep it securely closed when the hinge plates are installed. The hinge system is rather efficient, and the doors open and close without issue.

Â

Fig 007) – Next I installed the radiator to the firewall, the former doubling as a “lock” for the opening hood. The hood should be taped into place in the closed position while the radiator is installed. Before I performed this operation, I glued the heater box and battery into the engine bay, since the hood will not open far enough to allow easy access for installing these items (insert pic #7).

Fig 007a) – I then installed the taillight bezels from the back of the taillight panel to the body. The older issue’s taillights are molded in clear plastic, so I painted them with Tamiya clear red paint. Before installing the bezels I test-fitted the rear bumper into the opening and discovered that a 1/8″ section of the inboard openings on both sides of the body should be removed for the stock version (insert pic #7a here). This is noted in the instruction sheet on the older issue but noticeably absent on the newer issue’s instructions. This is a major gaffe on Revell’s part, and should be addressed if this kit is to be re-issued at a later date.

Moving on to the body installation, I had previously removed the “V”-shaped support spanning the interior opening in the bodies of both cars. Care must be taken during removal as I managed to cause a hairline crack down the middle of the trunk while removing the support at the rear on the older issue. Removal on the newer issue was seamless.

Fig 008) – I left the doors taped shut to keep them from flapping around during the process. The body installed quite easily, and seated rather nicely on the chassis. After the glue dried I removed the tape from the doors to check the door swing, which was fine. Unfortunately when I checked the swing on the driver’s side of the newer issue, the hinge plate popped off. This presented a real challenge as I did not wish to remove the body to replace the hinge plate. After pondering the situation, I came up with an idea. Calculating the proper angle to re-install the plate, I used my pin vise and a #80 drill bit to drill into the curved section of the plate just enough to grip it. I glued the hinge plate again, this time placing a spot of glue as close to the hinge as possible, then gently guided the plate into position, resting the pin vise itself against the top of the body. Once I let the glue dry thoroughly, I backed the drill bit out of the plate and re-tested the operation. Bingo! The plate stayed firm and the door swung without problems.

I did notice however, that the hood did not close all the way…the air cleaner prevented this from occurring. It was even more conspicuous after installing the expansion tank on the engine. The hose from the tank was 1/8″ short of the radiator, and 1/8″ too high. Not only that, the hood closed even farther away than before I installed it. Upon closer inspection, it seems the engine mounting points on the chassis are 1/8″ too high, making the engine sit up higher in front than it should. Unfortunately, by the time I discovered this I was unable to remove the engine from either car to make necessary adjustments since both were glued well, and I didn’t want to break anything attempting to force the issue. Hopefully this is a caveat to anyone wishing to build either issue. Both my examples therefore will have to be displayed with the hood raised.

Fig 009) – My next tasks were to install the completed dashboard and windshield assemblies onto the body. As unique as the dash installation process seems, it went quite smoothly. I had heard from a friend and fellow reviewer that the windshield and frame were very difficult to install, so I studied this phase of the build very closely beforehand. According to the instruction sheet, the clear windshield should attach to the chrome frame and then to the body. I took a different approach: I glued the glass to the body with Ambroid cement, since it doesn’t fog glass as does CA glue, waited until dry, then glued the frame to the glass using the Ambroid. It was a seamless operation! I then installed the rear-view mirror and sun visors to the frame with ease. Voila! The end result looks great with no glue smears or fogging at all.

Wrapping up the assembly process were the front bumper (with guards), outside mirrors, antenna, and fender ornaments. On the newer issue the modeler must open the holes in the bumper for the bumper guards whereas the older issue’s bumper guard holes are already open. The same applies to the holes for the mirrors, antenna, and fender ornaments. All these items installed without issue. I then used silver paint and a toothpick to detail the T-Bird logos on both hood and trunk, side “Thunderbird” scripts and door handles and locks, then applied Bare-Metal foil to the door louvers on the older issue. The newer issue covers all these items with decals…a nice touch! With the doors and hood raised, both cars strike a nice pose, although I would have liked to see the hood be able to raise more than the mechanics allow it to (insert pix #10-13)

Final impressions: Although not my favorite automotive subject, the ’58 Thunderbird is a handsome vehicle. For as old as the tooling is, assembly was trouble-free in a lot of areas on both kits, and I was quite impressed with the majority of the engineering aspects of this model, especially with the opening door and hood mechanisms. However, omissions concerning the engine mounting points and the removal of material between the taillights to incorporate the rear bumper (newer issue) soured my optimism for both issues. I like the fact Revell included decals for the seat inserts, door panels, and exterior scripts on the newer issue. Both cars’ tooling is pretty much identical, except for the added parts for the newer issue’s custom version. Unfortunately the newer issue contains way more flash than it should…the tooling should have been cleaned up before the re-issue was started especially on the chrome tree.

As a result of the issues I encountered during both builds, I would give both a 2-1/2 star rating out of five. The kit is quite buildable, but there are some flaws that should be corrected before the build begins. Would I build this kit again? Only if I were commissioned to do so…not for my own personal pleasure. Hopefully anyone who considers buying this kit reads this review first before beginning the assembly process…it would alleviate a lot of headaches afterward.  Â

Fig 999)

Donations Humbly Accepted

*All registered trademarks are the property of their respective brands.

Â

Â

Â