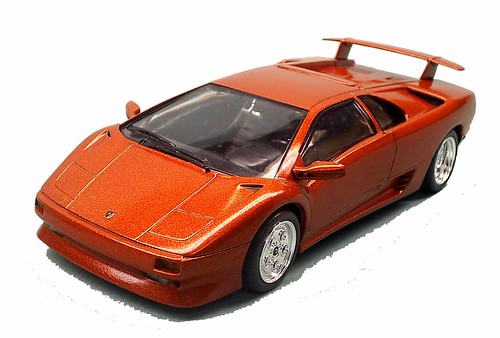

Lamborghini Diablo VT 85-0889 Revell 1:24 Review

RoR Step-by-Step Review 20120228* – Lamborghini Diablo VT 85-0889 Revell 1:24 Review

Click Here to Buy This Kit

Review and Photos by Marty and Stephanie Oberman

Although my last name is of German descent, I nonetheless take extreme pride in my Italian heritage through my mother’s side of the family. We Italians are famous for many things: great food, red wine, expensive silk suits, incurable passion and romanticism, and last but not least, sleek and fast supercars. The Lamborghini Diablo VT is no exception to this last category, and the 492h.p. V-12 engine is truly a testament to the outstanding design and engineering from my brethren from the “boot country”.

Â

One note: I discovered as I began this build, and this was verified later, that this kit’s tooling started life as a snap kit, before being re-issued as a Level 2 glue kit. The snap kit has been excellently reviewed already in this forum, and I used many helpful notes from it while building this kit. Throughout the build, I reamed out contact point holes and tabs after painting them in order to enable me to test fit many parts before committing to their placement with glue. I highly recommend the builder do the same.

Â

(Fig. #1) I started this beauty by stripping all the chromed engine pieces and painting them in a variety of Testor’s metalizer paints. The two-piece block/tranny, engine bottom, rocker covers, and front cover were all painted aluminum plate after being assembled as a unit. The molded in starter was painted magnesium and the rubber boot for the shift linkage flat black. I painted the engine mounts magnesium but saved them for later installation since they moved freely in their slots, and I did not wish to commit to gluing them in place until it came time to mount the engine into the chassis. The exhaust pipes and alternator were also painted magnesium, as were the belt assembly pulleys. The belts were detailed using flat black.

Â

(Fig. # 2) The engine itself assembled smoothly. One caveat, however: the instruction sheet shows the belt assembly and alternator being installed AFTER the rear axle has been placed in the chassis. I recommend these two items being installed before the rear axle, as the axle interferes with their installation. The exhaust pipes installed with no problem after the engine was placed onto the chassis. The engine mounts were glued into the engine sides then quickly installed into their respective pins on the chassis floor.

Â

(Fig. #7) The chassis consists of two major components: lower and upper; the latter of which also includes the platform-style interior floor, with center console and accelerator molded in. Both sections also contain the brake and wheel mounting setups. Step 2 of the instruction sheet directs the builder to install the tie rod to the two contact pins at the leading edge of the lower chassis. This is incorrect, as it should be installed to the two pins nearest the front axle, at the trailing edge of the front chassis pan. The builder would soon figure this out anyway, as the pins’ width does not accommodate the holes for the tie rod. Both the front and rear axles, painted aluminum plate metalizer with flat black bushings, installed without issue, and snuggled comfortably into their respective niches. The upper chassis pan then installed onto its lower counterpart with ease.

Â

(Fig. #8) The rear wheel well unit contains two sets of rear springs and left and right radiators, the latter of which resemble backward mud flaps. The front wheel well unit fits over the front spring/pedal assembly, which seats into a slot in front of the interior pan. Installation of these items was effortless. The chrome rims and accompanying wheel backs fit into the beefy tires with no problems, as contact points on both made them “dummy-proof” to install, and I painted the wheel backs Dupli-Color “Chrome” to match the rims.

Â

(Fig. #14) The interior components consist of dashboard with separate instrument gauge cowl, two-piece steering column with stalks, steering wheel, shifter, side door panels, and one-piece seats. A rear bulkhead separates the interior from the engine compartment.

Â

(Fig. #11) There are three sets of decals: instrument cluster (of which there are two varieties), upper console, and Lamborghini logo for the steering wheel center. All the decals snuggled in nicely, even the one for the multi-tiered dash center. Somehow I managed to misplace the shifter and lost it, so I scratch built one using a steel bristle from my wife’s hairbrush (shhhh…don’t tell her!!!) which, although not prototypically correct, nonetheless adequately sufficed. Assembly was straightforward and the satin black interior looks really nice when completed.

Â

(Fig. #6) The last item to be installed was the intake manifold assembly. I detail-painted all of the components using different metalizers and flat black for the hoses. I applied the decal, painted the “Lamborghini” lettering on the valve covers, and am quite proud of how it turned out. Installation was flawless.

I then turned my attention to the body. There are a number of components including a separate three-piece spoiler, engine cover with CHMSL bracket, engine cover, rear panel and rear bumper. I assembled the spoiler together and painted the underside as a unit, as I did with the rear panel and the underside of the rear bumper and engine cover/CHMSL (High Taillight). I then painted the areas of the body where these parts would reside, making sure I would be able to remove them after the painting process without damage. I painted the entire assembly Testor’s “Fiery Orange” One-Step lacquer, then clear-coated and waxed it. I then removed the parts for detailing. The color I selected for the car presented a unique challenge: how would I make the numerous orange turn signals and front side marker lights stand out against an orange paint job?

(Fig. #19) Since all lenses except for the taillights were clear plastic, I painted the backs of all the lenses with a silver Sharpie, installed them, then coated them with Tamiya clear orange paint. The back-up lenses, nestled in a black panel between the taillights, needed no further attention, as they stood out prominently against the black paint. The turn signal lenses, once painted, contrasted nicely with the body color. The taillights stood out nicely as well.

(Fig. #16) I swiped the CHMSL with a silver Sharpie, then painted it with Tamiya clear red, and it too stands out well.

(Fig. #22) The molded-in front side markers don’t stand out as well even with silver base and clear orange.

(Fig. #26) The rear side marker lights double as snap retainers for the rear bumper; a clever design feat by the Revell team. I painted them silver until the rear bumper was permanently installed, then dabbed Tamiya clear red on them once the rear bumper was in place.

(Fig. #17) Although difficult to see, I gave the molded-in red reflectors on the rear bumper the same treatment as the side marker lights, and they turned out well.

Â

(Fig. #21) The front turn signal lenses and driving lights, all clear plastic, were given the same treatment as the rear units, and the turn signal lenses were painted clear orange.

Â

(Fig. #23) The single-piece glass unit was given a black Sharpie treatment around the edges before being installed. Note: The engine cover should be installed before the glass, as the rear of the glass unit traps the engine cover hinges in place. The rear view mirror installed without issue, as did the glass for a nice snug fit using two pins on the underside of the roof and two corresponding holes in the upper part of the glass. The rear view mirror was installed with no issues. The upper frame installed easily and smoothly into the rear of the body.

I then installed the body onto the interior/chassis nose first, then carefully finagled the rear of the chassis around the rear body panel using an Exacto knife to coax the panel around the lips of the chassis. It soon snapped right into place, at which time I installed the two bumper supports and then the rear bumper itself. The rear bumper was quite difficult to install as the bumper supports preventing it from wrapping around the retainers on the body and snap into place. I ended up shaving material from the bumper supports to enable the bumper to snap into place. I then painted the retainers/side marker lights with Tamiya clear red. The side mirror lenses installed effortlessly, as did the exhaust pipes and chrome exhaust tips, although I was dismayed that Revell attached the tips to their respective tree by the exterior ends, not the interior ends where the removal of chrome would be less noticeable.

The final touches were applying decals of the “Diablo” and “VT” scripts to the rear panel, Lamborghini logos to the hood and wheel centers, and detail painting the “Lamborghini” script on the rear deck.

Â

(Fig. #43) The finished product looks great, with the exception of a rather large gap where the leading edge of the engine cover meets the roofline.

Â

(Fig. #39) Otherwise, the engine cover fits flush on the body, and stays in the open position when raised, instead of flopping back down into place.

Â

(Fig. #999) Final impressions: The more I worked on this kit the more impressed I was with its design and engineering in terms of parts fit and finish. Even though this particular subject matter is really not my cup of tea, I enjoyed it more and more as I went along with the assembly process. The only “major” issue with the kit itself was the rear bumper, and that ended up being a relatively easy fix. Any other issues were minor and not really worth mentioning, simply because there were so few of them. Would I build this kit again? Probably not, and ONLY because I’m not a fan of supercars. I do however HIGHLY recommend both this kit and its “snap” sister kit for both beginning and intermediate modelers, and in fact, this kit would make an excellent build for the beginner wishing to branch out into the world of glue kits. For all the above reasons I believe this kit merits a solid four stars out of five. And as we Italians would say…”manga!” (enjoy!)

*All Registered trademarks are the property of their respective brands.

Â

Â

Â